Borosilicate Glass Baking Dish Custom Square Glass Oven Tray

|

Usage

|

Heat Resistant Square Shape High Borosilicate Glass Baking Fish

|

|

Shape

|

Square

|

|

Temperature range

|

-40℃-300℃

|

|

Thermal shock temperature

|

120℃

|

|

Sample time

|

1.exsiting sample :within 7 days

2.new sample:within 20days after received the sample fee |

|

Payment method

|

30% deposit and 70% balance after received the copy of the BL

or L/C |

|

MOQ

|

3,000pcs

|

|

Delivery time

|

45-60 days after received the deposit

|

|

Model No.

|

Size

|

Capacity

|

Pack

|

|

CZ-BWS-07L

|

20.6*20.6*4.8cm

|

1000ml

|

24pcs

|

|

CZ-BWS-16L

|

25.8*25.8*5.7cm

|

1800ml

|

12pcs

|

|

CZ-BWS-24L

|

29.8*29.8*6.3cm

|

3000ml

|

12pcs

|

Introduction to Borosilicate Glass Bakeware

Borosilicate glass is renowned for its durability and resistance to thermal shock, making it a popular choice for kitchenware. Canzo Glassware, with over 14 years of experience in borosilicate glass manufacturing, offers a wide range of glass products, including custom square glass baking dishes. This article delves into the advantages of using borosilicate glass bakeware, the customization options available, and why Canzo Glassware is a leader in the industry.

Advantages of Borosilicate Glass Baking Dish

Borosilicate glass baking dish are favored in kitchens worldwide due to their superior qualities. Here are some key benefits:

- Thermal Shock Resistance: Unlike regular glass, borosilicate glass can withstand rapid temperature changes without cracking.

- Durability: It is highly resistant to scratches and stains, ensuring long-lasting use.

- Non-reactive Surface: The non-porous surface does not absorb odors or flavors, maintaining the purity of your food.

- Transparency: The clear glass allows you to monitor the baking process without opening the oven door.

These features make borosilicate glass baking dishes an excellent investment for any kitchen.

Customization Options for Glass Baking Dishes

Canzo Glassware offers a variety of customization options to meet your specific needs. Whether you’re looking for a unique size, color, or design, they can accommodate your requirements. Here are some customization options available:

- Custom Sizes and Shapes: From standard square trays to unique shapes, Canzo can create a baking dish that fits your needs.

- Color Options: Choose from a range of colors to match your kitchen décor or personal preference.

- Logo and Branding: Add your logo or any design to personalize your baking dish.

- Packaging Services: Customized packaging options ensure that your products arrive safely and are presentation-ready.

These flexible options make it easy to create a baking dish that is uniquely yours.

Canzo Borosilicate Glassware Commitment to Quality

With over 14 years of experience, Canzo Glassware has built a reputation for excellence in borosilicate glass manufacturing. They adhere to stringent quality control measures to ensure each product meets high standards. Here are some reasons why Canzo stands out:

- Extensive Product Range: Over 3000 different glass food containers, bakeware, and storage jars.

- Wholesale Pricing: Competitive pricing for bulk orders.

- Flexible MOQ: Minimum order quantities that cater to both small and large businesses.

- Sustainable Practices: Commitment to environmentally friendly manufacturing processes.

Canzo glassware dedication to quality and innovation has made them a trusted name in the industry.

Applications of Custom Glass Baking Dishes

Custom borosilicate glass baking dishes are versatile and can be used in various settings, including:

- Home Kitchens: Ideal for everyday baking and cooking needs.

- Restaurants and Cafes: Durable and stylish options for professional kitchens.

- Gift Items: Customized dishes make thoughtful and practical gifts.

- Retail: Unique designs for specialty stores.

The adaptability of custom glass baking dishes makes them suitable for a wide range of applications.

Conclusion

Borosilicate glass baking dishes offer unmatched durability, versatility, and customization options, making them a valuable addition to any kitchen. Canzo Glassware, with its extensive experience and commitment to quality, provides a wide range of products and customization services to meet diverse needs. Whether for personal use, professional kitchens, or retail, Canzo custom glass baking dishes are designed to meet the highest standards of performance and aesthetics.

Explore the possibilities with Canzo Glassware and elevate your baking experience with custom borosilicate glass baking dishes.

Factory Introduction

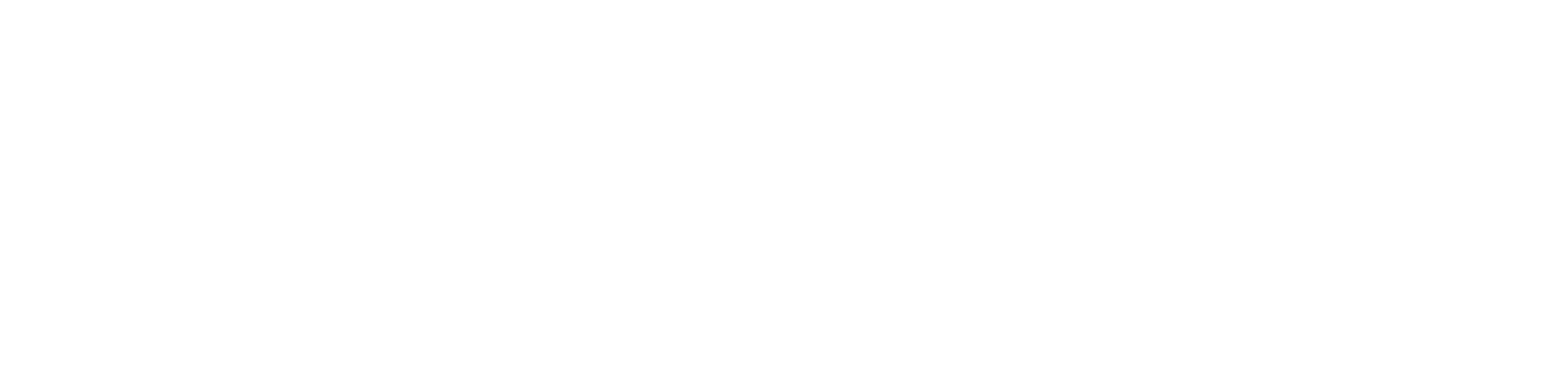

Borosilicate Glassware Production Process

At Canzo High Borosilicate Glassware Factory, we produce high-quality borosilicate glassware through a meticulous process. Starting with the selection and mixing of high-purity raw materials, the mixture is melted at high temperatures to form molten glass. This molten glass is then poured into moulds, pressed to remove air bubbles, and fire-polished to enhance clarity. The glassware undergoes annealing, a controlled cooling process to relieve internal stresses and ensure durability. After a thorough quality inspection, the finished products are carefully packed for distribution. This process ensures that our glass food containers, bakeware, jars, and coffee mugs meet the highest standards of quality and durability.

Custom Borosilicate Glassware Packaging

With 16 years of industry experience, Canzo High Borosilicate Glassware Factory excels in providing the most suitable packaging solutions for our customers. We offer expert recommendations and can customize packaging design and production to meet specific customer needs. Our packaging solutions ensure the highest standards of protection and presentation for our borosilicate glassware products. These packages can be personalized in design, reflecting your brand’s unique identity while guaranteeing the safety and integrity of the borosilicate glassware. We are dedicated to delivering packaging that not only enhances the aesthetic appeal but also provides robust protection during transportation and handling.

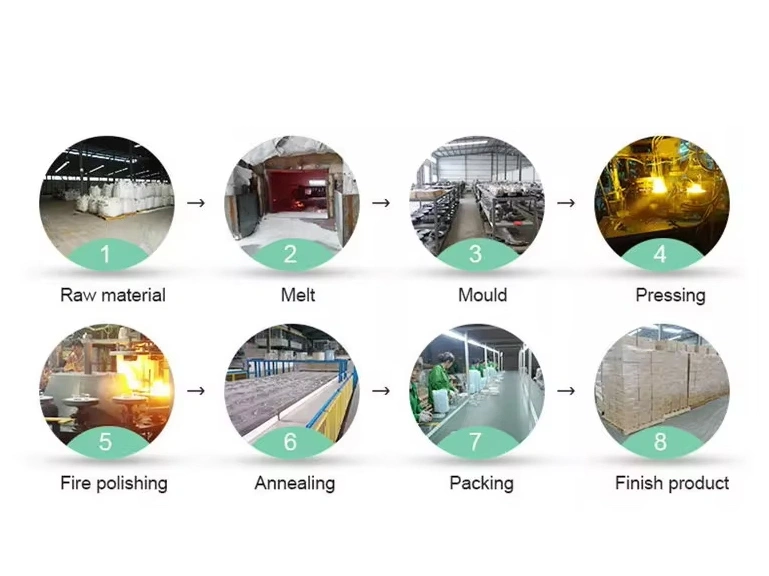

Borosilicate Glassware Inspection Standard

Final Quality Inspection

Once annealed, each piece of glassware undergoes a comprehensive final inspection. This includes checking for uniform thickness, clarity, and absence of defects. Our inspectors use precise measurement tools and visual inspection techniques to ensure that every item meets our high standards.

Packaging Inspection

Finally, our packaging solutions are also subject to stringent inspection standards. We provide personalized packaging designs that ensure both the safety and aesthetic appeal of our products. Packaging is tested for durability and effectiveness in protecting the glassware during transportation and handling.

FAQ of Borosilicate Glass Baking Dish Custom Square Glass Oven Tray

We are the leading heat-resistant high borosilicate glassware factory in China.

Round / Rectangle/ Square Borosilicate Heat-resistant Glass Food Storage Containers, Borosilicate Bakeware, Borosilicate Glass jar, Mixing Bowl; Measuring Cup; Borosilicate Glass Cup etc.

sually our MOQ is 1000 pcs, but we can accept lower quantity for your trial order. Please feel easy to tell us how many pieces you need, we will calculate the cost reasonably, hoping you can place mash orders after checking quality of our products and knowing our service.

We have pass the LFGB, GDCCRF certificates as well as audits for some of famous companies such as Walmart, BSCI, WCA, Avon etc. We have own QC to check mass productions in factory line. All products can pass the tests of SGS, BV and TUV.

For existing clients, the most commonly used payment method is a 30% deposit with 70% payment before shipment. We also support other payment methods such as L/C, T/T, PayPal, and Alibaba Assurance.

All of products can pass the FDA, LFGB and DGCCRF certificate test. We obtained the certification of environment (ISO14001) and quality (ISO9001) management system.

For existing samples, it takes 3-4 days. If you want your own designs,it will take 7~10days, subject to the difficulty of your designs . Anyway we will response fast to your request.

For our cooperate clients, the most commonly chosen shipping term is FOB, usually FOB Qingdao. However, we also support all other terms, including EXW, CIF, DAP, and DDP.

It depends on the quantity of your order. For orders of less than 5000 units, our production lead time is typically 25-30 days. Our sales representative will provide you with the exact lead time when communicating your order.