Personalized Christmas Glass Food Storage Containers

Usage | Food, fruit, candy, coffee bean |

Packaging Details | Polybag + corrugated box + cartons |

Capacity | 200ml 250ml 300ml 400ml 500ml 600ml 750ml 1000ml 1250ml 1800ml 2000ml 3000ml |

MOQ | 3000 |

Material | Borosilicate glass |

Color | Transparent or customized |

Sample | Yes |

Shipping | By Air/By Sea/By Express |

Introduction to Personalized Christmas Glass Food Storage Containers

As the holiday season approaches, the demand for festive and functional kitchenware soars. Personalized Christmas glass food storage containers are an ideal solution for both practical storage needs and adding a touch of holiday cheer to your kitchen. Made from high-quality borosilicate glass, these containers offer durability, versatility, and a festive aesthetic that enhances your holiday experience.

Features and Specifications

Personalized Christmas glass food storage containers are designed to meet a variety of storage needs. Here are the key features and specifications:

- Usage: Suitable for storing food, fruits, candy, and coffee beans.

- Packaging Details: Packaged in polybags, corrugated boxes, and cartons to ensure safe delivery.

- Capacity: Available in a wide range of sizes from 200ml to 3000ml.

- MOQ (Minimum Order Quantity): 3000 pieces.

- Material: Made from high-quality borosilicate glass, known for its durability and resistance to thermal shock.

- Color: Transparent, showcasing the contents beautifully.

- Sample Availability: Yes, samples are available upon request.

- Shipping Options: Can be shipped by air, sea, or express, depending on customer preference.

Borosilicate Glassware Manufacturing and Production

With a robust annual output value exceeding $100 million, these personalized Christmas glass food storage containers are produced with meticulous attention to detail. The manufacturing process includes:

- Wholesale Manufacturing: High production capacity ensures the ability to meet large orders efficiently.

- OEM and ODM Processing: Customization options are available, allowing for personalized designs and specifications.

- Material Quality: Constructed from high borosilicate glass, which can withstand temperatures ranging from -20°C to 560°C, ensuring durability and versatility.

Factory Audits and Certifications

Ensuring the highest standards of quality and safety, the manufacturing facilities are regularly audited and certified by reputable organizations:

- Factory Audits: Conducted by BICI, COSTCO, and WALMART to ensure compliance with industry standards.

- Certifications: FDA, LFGB, DGCCRF, ROHS, REACH, FSC, and MSDS certifications confirm the safety and quality of the products.

Performance and Durability

Personalized Christmas glass food storage containers are designed to perform under various conditions while maintaining their integrity and functionality:

- Thermal Shock Resistance: With a resistance of 120℃, these containers can handle sudden temperature changes without cracking.

- Heat Resistance: Capable of withstanding temperatures from -20℃ to 560℃, making them suitable for both freezer and oven use.

Experience and Expertise

Canzo Glassware, with 14 years of experience in the borosilicate glass industry, specializes in B2B custom wholesale business. Our expertise in producing high-quality glassware ensures that customers receive products that meet their exact needs and specifications. While our primarily focus on borosilicate filed, our products are designed to serve various commercial and industrial purposes.

Conclusion

Personalized Christmas glass food storage containers are an excellent addition to any kitchen during the holiday season. Combining festive designs with practical features, these containers cater to a wide range of storage needs while enhancing the holiday spirit. With high-quality borosilicate glass construction, extensive customization options, and rigorous quality standards, these containers are a perfect choice for businesses looking to offer unique and functional holiday-themed kitchenware.

Factory Introduction

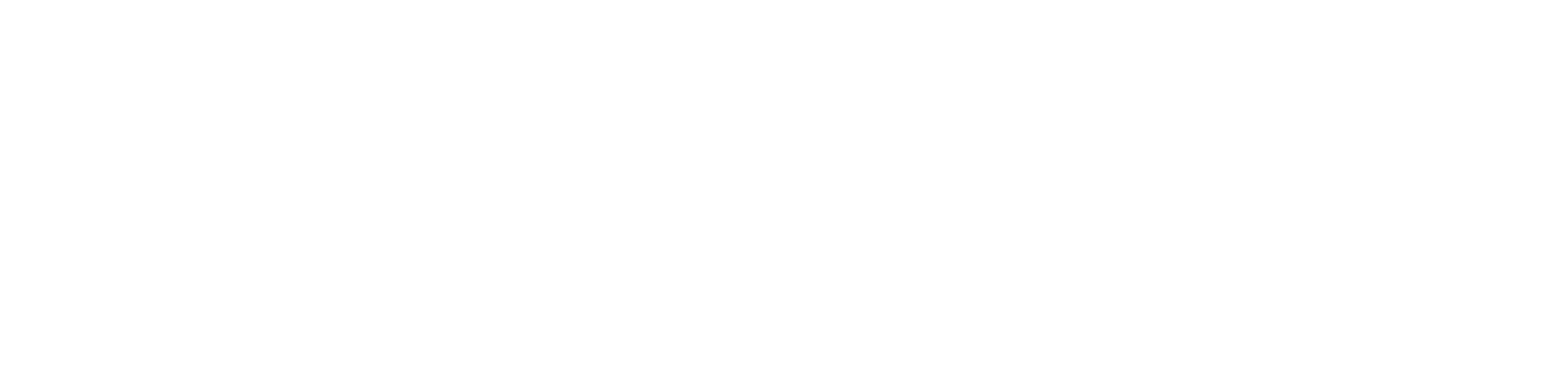

Borosilicate Glassware Production Process

At Canzo High Borosilicate Glassware Factory, we produce high-quality borosilicate glassware through a meticulous process. Starting with the selection and mixing of high-purity raw materials, the mixture is melted at high temperatures to form molten glass. This molten glass is then poured into moulds, pressed to remove air bubbles, and fire-polished to enhance clarity. The glassware undergoes annealing, a controlled cooling process to relieve internal stresses and ensure durability. After a thorough quality inspection, the finished products are carefully packed for distribution. This process ensures that our glass food containers, bakeware, jars, and coffee mugs meet the highest standards of quality and durability.

Custom Borosilicate Glassware Packaging

With 16 years of industry experience, Canzo High Borosilicate Glassware Factory excels in providing the most suitable packaging solutions for our customers. We offer expert recommendations and can customize packaging design and production to meet specific customer needs. Our packaging solutions ensure the highest standards of protection and presentation for our borosilicate glassware products. These packages can be personalized in design, reflecting your brand’s unique identity while guaranteeing the safety and integrity of the borosilicate glassware. We are dedicated to delivering packaging that not only enhances the aesthetic appeal but also provides robust protection during transportation and handling.

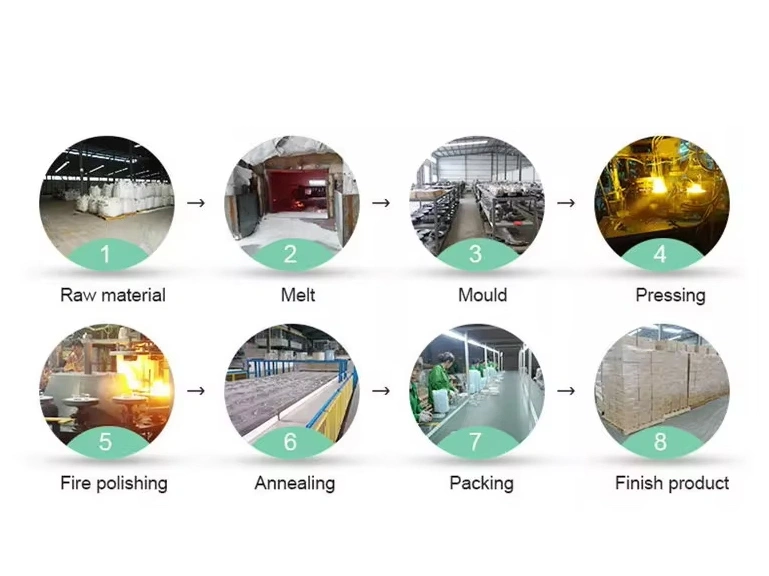

Borosilicate Glassware Inspection Standard

Final Quality Inspection

Once annealed, each piece of glassware undergoes a comprehensive final inspection. This includes checking for uniform thickness, clarity, and absence of defects. Our inspectors use precise measurement tools and visual inspection techniques to ensure that every item meets our high standards.

Packaging Inspection

Finally, our packaging solutions are also subject to stringent inspection standards. We provide personalized packaging designs that ensure both the safety and aesthetic appeal of our products. Packaging is tested for durability and effectiveness in protecting the glassware during transportation and handling.

FAQ of Personalized Christmas Glass Food Storage Containers

We are the leading heat-resistant high borosilicate glassware factory in China.

Round / Rectangle/ Square Borosilicate Heat-resistant Glass Food Storage Containers, Borosilicate Bakeware, Borosilicate Glass jar, Mixing Bowl; Measuring Cup; Borosilicate Glass Cup etc.

sually our MOQ is 1000 pcs, but we can accept lower quantity for your trial order. Please feel easy to tell us how many pieces you need, we will calculate the cost reasonably, hoping you can place mash orders after checking quality of our products and knowing our service.

We have pass the LFGB, GDCCRF certificates as well as audits for some of famous companies such as Walmart, BSCI, WCA, Avon etc. We have own QC to check mass productions in factory line. All products can pass the tests of SGS, BV and TUV.

For existing clients, the most commonly used payment method is a 30% deposit with 70% payment before shipment. We also support other payment methods such as L/C, T/T, PayPal, and Alibaba Assurance.

All of products can pass the FDA, LFGB and DGCCRF certificate test. We obtained the certification of environment (ISO14001) and quality (ISO9001) management system.

For existing samples, it takes 3-4 days. If you want your own designs,it will take 7~10days, subject to the difficulty of your designs . Anyway we will response fast to your request.

For our cooperate clients, the most commonly chosen shipping term is FOB, usually FOB Qingdao. However, we also support all other terms, including EXW, CIF, DAP, and DDP.

It depends on the quantity of your order. For orders of less than 5000 units, our production lead time is typically 25-30 days. Our sales representative will provide you with the exact lead time when communicating your order.